Immersed tunnels have been in widespread use for about 100 years.

Over 150 have been constructed all over the world, about 100 of them for road or rail schemes. Others include water supply and electricity cable tunnels.

These tunnels are a very good solution everytime there is a main course of water that need to be traversed. Once completed, an immersed tunnel is no different operationally from any other tunnel. However, it is built in a completely different way.

Advantages and perceived problems

Whenever there is a need to cross water, an immersed tunnel should be considered. The final choice of crossing type will of course depend on many factors. The table below gives an indication of circumstances which favour immersed tunnelling.

- Immersed tunnels can be built shallow, permitting shorter tunnels and flatter alignments than bored tunnels.

- Immersed tunnel cross sections are highly versatile, making them particularly suitable for wide highways and combined road/railway crossings.

- Typically built in between 5m and 30m of water, although schemes have been postulated for 100m depth. Submerged floating tunnel technology (see next chapter) will make water depth immaterial.

- Most types of ground can be dealt with, including soft alluvial materials. Conditions unsuited to bored tunnelling do not usually pose a problem. Design for earthquake zones has shown to be perfectly feasible.

- Immersed tunnels are often prefabricated remote from the final immersion site, allowing installation in extremely congested (e.g. urban) locations where nearby land is not available.

- Dredging operations present an opportunity to reshape riverbanks and coastlines as part of a tunnel construction scheme. They are, for example, commonly associated with land reclamation schemes.

-

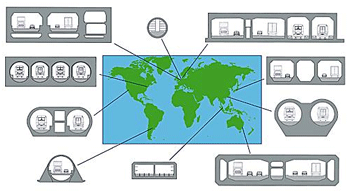

Immersed tunnels do not have to be circular in cross section. Almost any cross section can be accommodated, making immersed tunnels particularly attractive for wide highways and combined road/rail tunnels. Some examples of realised cross sections are shown below.

- Immersed tunnels can be placed immediately beneath a waterway. In contrast, a bored tunnel is usually only stable if its roof is at least its own diameter beneath the water. This allows immersed tunnel approaches to be shorter and/or approach gradients to be flatter - an advantage for all tunnels, but especially so for railways.

- Immersed tunnels can be constructed in ground conditions which would preclude bored tunnelling or render it prohibitively expensive, such as the soft alluvial deposits characteristic of large river estuaries. They can also be designed to deal with the forces and movements in earthquake conditions, to be placed in very soft ground in an area prone to significant earthquake activity.

- Bored tunnelling is a continuous process in which any problem in the boring operation threatens delay to the whole project. Immersed tunnelling creates three operations - dredging, tunnel element construction and tunnel installation, which can take place concurrently, thus moderating programme risk considerably. Partly for this reason, an immersed tunnel is generally faster to build than a corresponding bored tunnel.

Immersed tunnels are sometimes perceived by newcomers to the technology as "difficult" due to the presence of marine operations. In reality though, the technique is often less risky than bored tunnelling and construction can be better controlled. The marine operations, though unfamiliar to many, pose no particular difficulties. The perceived problems include:

- Dredging technology has improved considerably in recent years, and it is now possible to remove a wide variety of material underwater without adverse effects on the environment of the waterway.

- Interference with navigation: On busy waterways, it is sometimes assumed that construction of an immersed tunnel would be impractical as it would interfere with shipping. In fact, such tunnels have been successfully built in some exceptionally busy waterways without undue problems.

- It is often assumed that the process of building a tunnel in water, rather than boring through the ground beneath it will increase the likelihood of leakage. In fact, immersed tunnels are nearly always much drier than bored tunnels, due to the above-ground construction of the elements. Underwater joints depend on robust rubber seals which have proved effective in dozens of tunnels to date.