Subaquatic Tunneling

Traditional immersed tunnelling results in a tunnel buried beneath the waterway which it traverses.

Construction procedure

|

A trench is dredged in the bed of the water channel. |

|

Tunnel elements are constructed in the dry, for example in a casting basin, a fabrication yard, on a ship-lift platform or in a factory unit. |

|

The ends of the element are then temporarily sealed with bulkheads. |

|

Each tunnel element is transported to the tunnel site - usually floating, occasionally on a barge, or assisted by cranes. |

|

The tunnel element is lowered to its final place on the bottom of the dredged trench. |

|

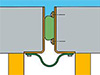

The new element is placed against the previous element under water. Water is then pumped out of the space between the bulkheads. |

|

Water pressure on the free end of the new element compresses the rubber seal between the two elements, closing the joint. |

|

Backfill material is placed beside and over the tunnel to fill the trench and permanently bury the tunnel, as illustrated. |

|

Approach structures can be built on the banks before, after or concurrently with the immersed tunnel, to suit local circumstances. |

New possibilities: Floating tunnels

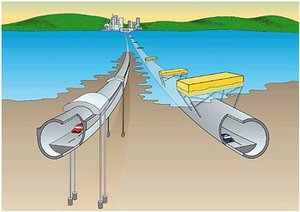

Traditional immersed tunnelling results in a tunnel buried beneath the waterway which it traverses. A new development- the submerged floating tunnel - consists of suspending a tunnel within the waterway, either by tethering a buoyant tunnel section to the bed of the waterway, or by suspending a heavier-than-water tunnel section from pontoons.

This technique has not yet been realised, but one project, in Norway, is currently in the design phase. The submerged floating tunnel allows construction of a tunnel with a shallow alignment in extremely deep water, where alternatives are technically difficult or prohibitively expensive.

Likely applications include fjords, deep, narrow sea channels, and deep lakes.