Mechanized tunneling

The machines usually found in nowadays tunnels are

Main beam TBMs (or open TBMs)

Shield TBMs

Compressed air

Slurry Shield

EPBS shield

To Know more

Mechanized tunneling (as opposed to conventional techniques) are all the tunneling techniques in which excavation is performed mechanically by means of teeth, picks or disks.

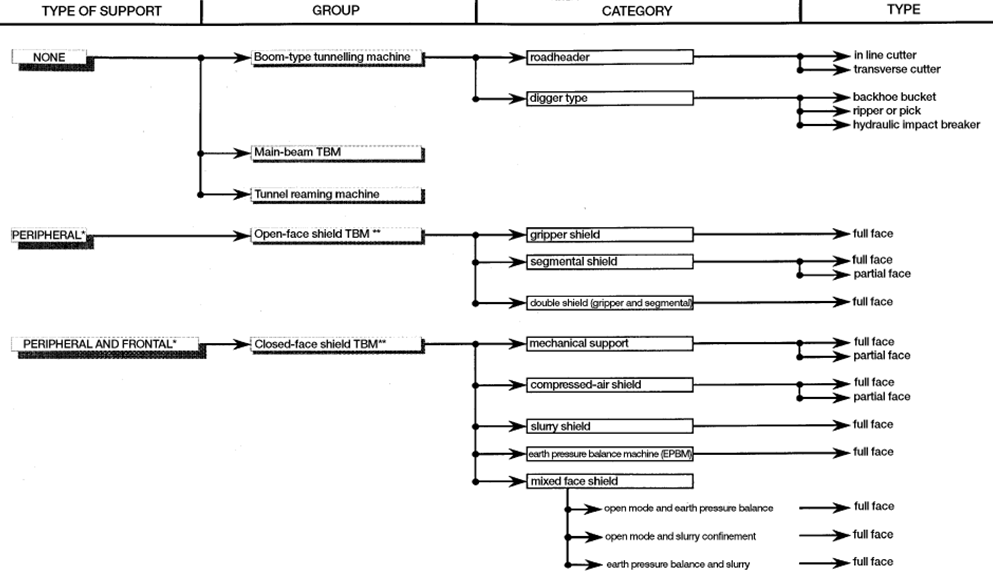

These tunneling techniques comprise then a wide range of different machines, from the simplest like backhoe diggers to the most complicated like confinement-type shield TBMs. These machines not only carry out the excavation of the ground, sometimes they also provide support.

This support can be just peripheral (like in the case of shield TBMs) or also being applied to the front (Earth pressure TBMs or Slurry Shields for instance).

Mucking is also performed automatically by these machines in the majority of cases, as it is the application of permanent support like in the case of shields, where precast concrete elements are placed directly by the machine.

As compared to conventional tunneling, different advantages and drawbacks can be stated for mechanized tunneling:

| Advantages | Drawbacks |

|---|---|

| Enhanced health and safety conditions for the workforce | Lack of flexibility |

| Industrialization of the tunneling process | Difficult adaptation to unexpected geological and hydro-geological conditions |

| Possibility of crossing complex hydro-geological conditions | Not economically optimized for short tunnels |

| Good quality of the finished product | Long time needed for the installation |

Classification of Mechanized Tunnelling Techniques