Definition

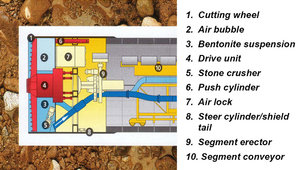

Slurry shields are TBM fitted with a full face cutterhead which provides face support by pressurizing boring fluid inside the cutterhead chamber.

These machines are most suited for tunnels through unstable material subjected to high groundwater pressure or water inflow that must be stopped by supporting the face with a boring fluid subjected to pressure.

Principle

The cutterhead acts as the means of excavation, whereas face support is provided by slurry counterpressure, namely a suspension of bentonite or a clay and water mix (slurry).

This suspension is pumped into the excavation chamber where it reaches the face and penetrates into the ground forming the filter cake, or the impermeable bulkhead (fine ground) or impregnated zone (coarse ground) which guarantees the transfer of counterpressure to the excavation face.

Excavated debris by the tools on the rotating cutterheads consists partly of natural soil and partly of the bentonite or clay and water mixture (slurry).

This mixture is pumped (hydraulic mucking) from the excavation chamber to a separation plant located on the surface which enables the bentonite-clay slurry to be recycled.

Main components

The main components of the machine are:

- Cutterhead, fitted out with discs, blades or teeth

- Protective Shield, containing all the main components of the machine. The front part is sealed by a bulkhead which guarantees the separation between the shield and the excavation chamber (pressurized) containing the cutterhead

- Longitudinal Thrust jacks

- Mud and debris separation system (normally located on the surface)

An special kind of slurry shield are the hydroshields, with an identical functioning principle to the slurry shields, with the only difference being the way of transferring the counterpressure to the face.

In the closed slurry shield in which the counterpressure is compensated inside the excavation chamber, there is the addition of a metal buffer which creates a chamber partially filled with air and connected to a compressor.

The result is the possibility of adjusting the counterpressure at the face independent of the hydraulic circuit (supply of bentonite slurry and mucking of slurry and natural ground).

Main field of application

These machines are specially suited to excavate ground with limited self-supporting capacity. In granulometric terms, slurry shields are mainly suitable for excavation in sand and gravels with silts.

The installation of a crusher in the excavation chamber allows any lumps, which would not pass through the hydraulic mucking system to be crushed. The use of disc cutters enables the machine to excavate in rock. Polymers can be used to excavate ground containing much silt and clay.

These machines are also specially suited for working in the presence of pressurized groundwater.

(Source: Recommendations and guidelines for tunnel boring machines – Working group 14 ITA)