Definition

Air compressed TBMs are tunnel boring machines where compressed air is used to counteract the hydrostatic ground pressure exerted against the cutterhead.

These machines are specially suited for excavation in unstable soils with the presence of water.

Principle

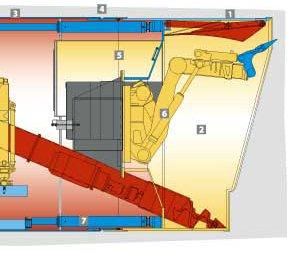

In compressed air closed shields the rotating cutterhead acts as the means of excavation whereas face support is ensured by compressed air at a sufficient level to balance the hydrostatic pressure of the ground.

Debris is extracted from the pressurized excavation chamber using a ball valve-type rotary hopper and then conveyed to the primary mucking system.

Main components

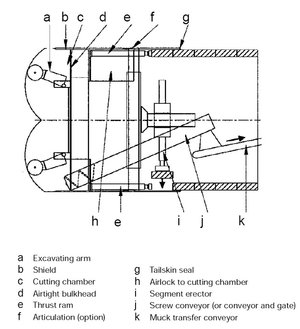

The main components of the machine are:

- The cutterhead (blades and teeth)

- The protective cylindrical shield containing all the main components of the machine. The front part is closed by a bulk head, which guarantees the separations between the excavation chamber (pressurized), housing the cutterhead, and the zone containing the machine components (unpressurized)

- Longitudinal thrust jacks

A special kind of compressed air shield is the compressed air open shield. As in the case of the open shields, face excavation is achieved using a roadheader, whereas face support is provided by compressed air in sufficient quantities to balance the hydrostatic pressure of the ground.

Main field of application

These machines are specially suited for the excavation of ground lacking self-supporting capacity and with medium to low permeability levels, where water is present.

Higher permeability can be locally reduced by injecting bentonite slurry onto the excavation face. The operating limit of the machine is the maximum pressure applicable based on regulations for the use of compressed air in force in different countries.

(Text and images source: Recommendations and guidelines for tunnel boring machines – Working group 14 ITA)